| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Hengxing |

| Certification : | ISO,CE |

| Model Number : | 900*1800-3200*4500 |

| Price : | negotiate |

| Delivery Time : | 7-35days after receipt of the downpayment |

| Payment Terms : | T/T,L/C |

| Supply Ability : | 100 sets per year |

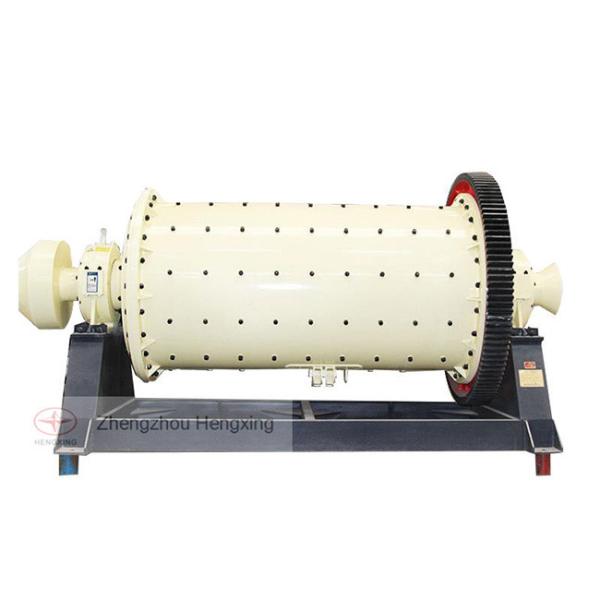

High Quality Wet Type Silicate Ball Mill /Silica Sand Ball Mill Equipment With Competitive Price

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, new-type building material, silicate, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. and the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

Ball mill working principle:

Model | Shell rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Motor power(kw) | Weight(t) |

Ø900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Ø900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Ø1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Ø1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Ø1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Ø1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Ø1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

Ø1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Ø1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

Ø1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Ø1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

Ø1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

Ø2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

Ø2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

Ø2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

Ø2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Ø2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Ø2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

Ø2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

Ø2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

Ø2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

Ø2700*4000 | 20.7 | 40 | <=25 | 0.074-0.4 | 12-80 | 400 | 94 |

Ø2700*4500 | 20.7 | 48 | <=25 | 0.074-0.4 | 12-90 | 430 | 102 |

Ø3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | ----- | 800 | 137 |

1. Large application range, simple structure and convenient maintenance;

2. Large capacity and continuous work are obvious advantages;

3. Various barrel lining and grinding media, excellent corrosion resistance;

4. Installation and adjustment are very convenient and easy to operate.

5.Cylinder is rolled and welded with Q235B steel plate. (the steel thickness is generally 1/100 of the cylinder diameter, for example ball mill of Φ1500, the steel plate thickness is 16 mm), the material of inlet and outlet hollow shaft is ZG35.

6.The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This machine run steadily and works reliably.Chi

|